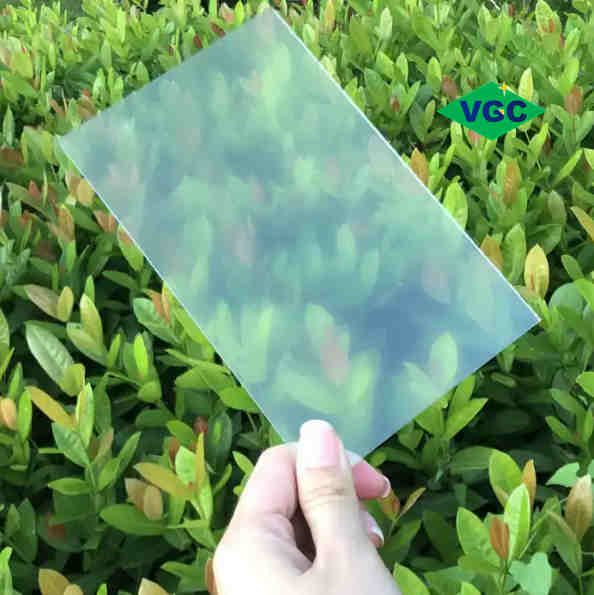

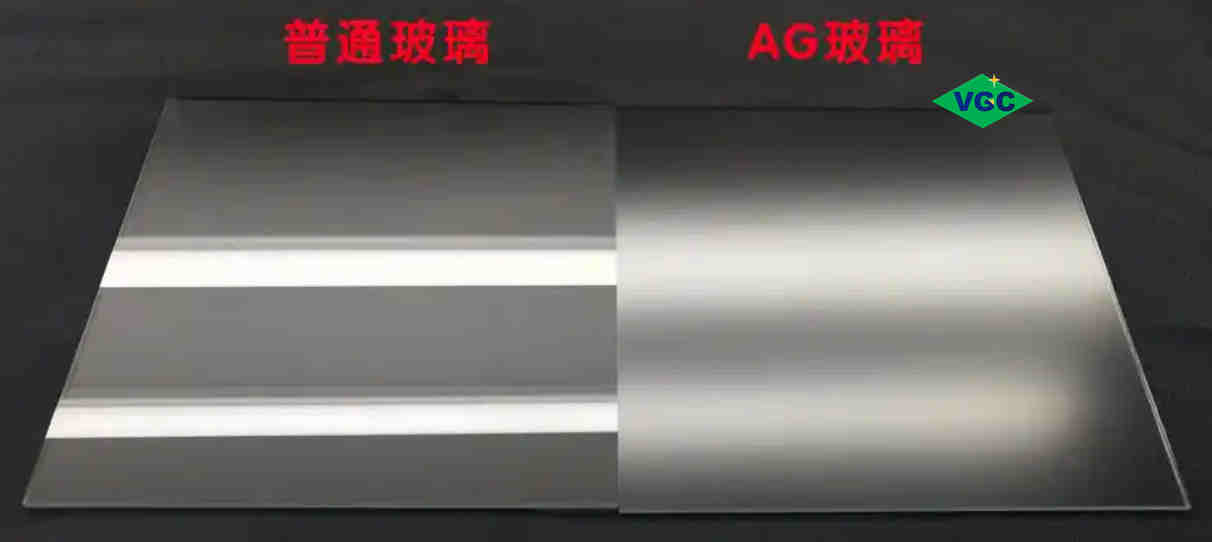

Discover VGC high-quality Glare Reduction Glass and Matte Glass, designed to minimize reflections and improve visibility. As a leading manufacturer, we provide durable, anti-glare solutions that enhance screen clarity and offer a more comfortable viewing experience for various applications.

Glare Reduction Glass China Factory

Advanced Manufacturing of Glare Reduction Glass (Matte Glass)

As a leading manufacturer specializing in advanced glass solutions, we produce high-quality Glare Reduction Glass ( Matte Glass) tailored for diverse applications, including automotive displays, consumer electronics, and architectural elements.

Glare Reduction Glass Manufacturing Process

VGC Glare Reduction Glass is engineered to minimize reflections and enhance visual clarity. The manufacturing process involves:

-

Raw Material Selection: We source premium silica sand, soda ash, and other additives to ensure the glass meets stringent optical standards.

-

Melting: The raw materials are melted in a furnace at approximately 1,500°C, forming a homogeneous molten glass.

-

Forming: The molten glass is drawn onto a molten tin bath, a process known as the float method, resulting in a uniform thickness and flat surface.

-

Surface Treatment: We apply a chemical etching process to the glass surface, creating micro-roughness that diffuses incident light, thereby reducing glare. This treatment enhances the viewing experience by minimizing reflections without compromising image clarity.

-

Annealing: The treated glass undergoes controlled cooling in an annealing lehr to relieve internal stresses, ensuring durability and stability.

-

Quality Control: Each glass sheet is rigorously inspected for optical properties, surface uniformity, and dimensional accuracy to meet industry standards.

Matte Glass Manufacturing Process

Our Matte Glass offers a non-reflective, diffused finish, ideal for applications requiring privacy or aesthetic appeal. The manufacturing steps include:

-

Raw Material Preparation: We select high-quality glass substrates, ensuring they are free from contaminants that could affect the matte finish.

-

Surface Treatment: The glass surface is subjected to chemical etching or sandblasting techniques to create a uniform matte texture. This process involves applying an acidic solution or abrasive particles to the glass surface, resulting in a frosted appearance that diffuses light and reduces glare.

-

Cleaning and Drying: Post-treatment, the glass is thoroughly cleaned to remove any residual chemicals or abrasive particles, followed by drying to prevent water spots.

-

Annealing: The glass is slowly cooled in an annealing lehr to relieve internal stresses, enhancing its strength and durability.

-

Quality Assurance: We conduct comprehensive inspections to ensure the matte finish meets the desired specifications, including uniformity, haze level, and surface integrity.

Applications

-

Automotive Industry: Enhancing display screens and interior panels to improve visibility and reduce glare.

-

Consumer Electronics: Used in monitors,blackboards, meeting boards, smartphones, and tablets to provide clearer displays and reduce eye strain.

-

Architecture: Applied in windows and partitions to offer privacy and aesthetic appeal while maintaining natural light diffusion.

Vehicle Nano Coating AG Glass

Automotive Display Glass China Supplier

blackboard AG glass Factory