About the Good Price Large Size Silver Mirror Glass Manufacturer-VGC China Your Best Supplier

VGC is Large Size Silver Mirror Glass Supplier, China Big Size Mirror Sheets Manufacturer.

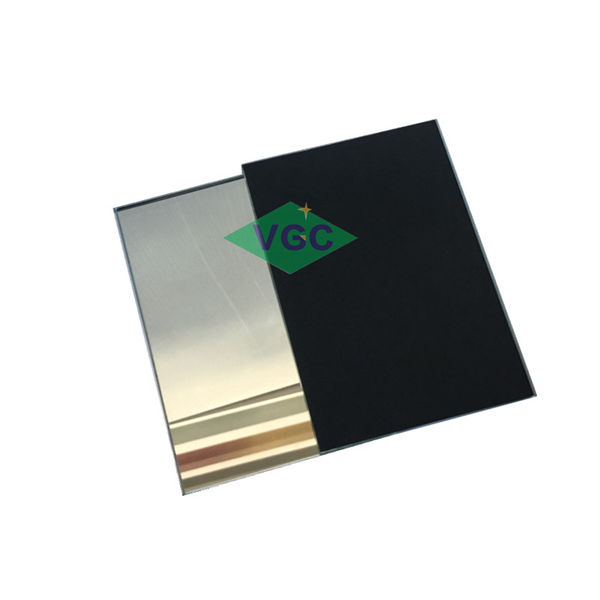

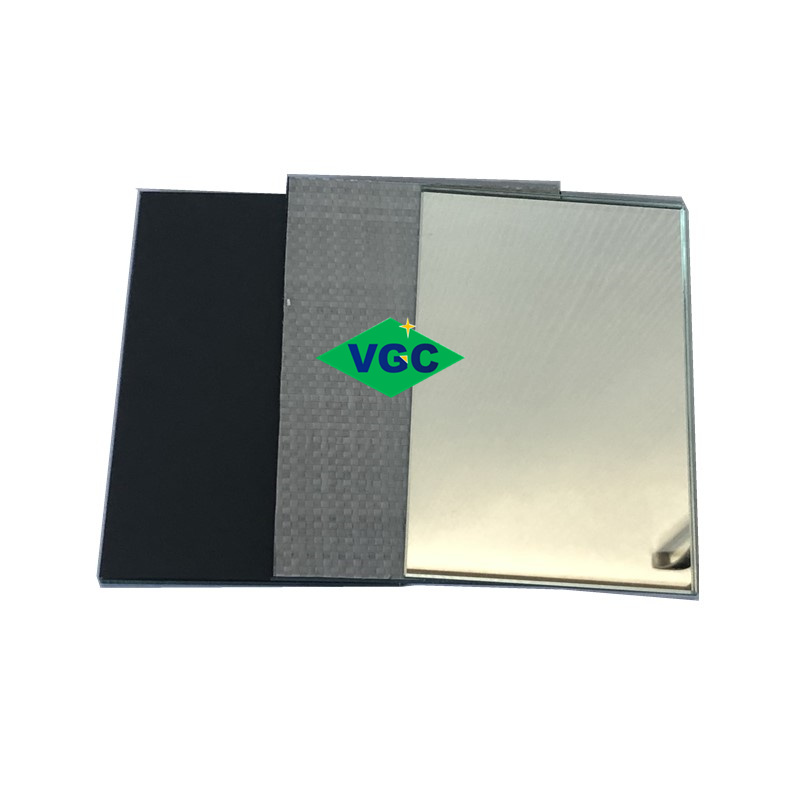

Large Size Silver mirror glass is a type of glass that has been coated with a thin layer of silver metal on one side. This coating is what gives the glass its reflective properties and allows it to function as a mirror.

The process of creating silvered mirror glass typically involves applying a layer of silver nitrate or another silver compound to the surface of the glass, followed by a reducing agent that converts the silver ions into metallic silver. The resulting layer of silver is usually protected by a layer of paint or other protective coating.

Silvered mirror glass is used in a variety of applications, including as a decorative element in architecture, as a component of reflective optics in telescopes and other scientific instruments, and in household mirrors.

| Item | Large Size Silver Mirror Glass |

| Thickness | 2mm/3mm/4mm/5mm/6mm/8mm |

| Standard Sizes | 1600mm*2200mm;1220mm*1830mm;1524mm*2134mm; 1830mm*2440mm; 2134mm*3300mm; 2250mm*3300mm; 2440mm*3300mm; 2440mm*3660mm |

| Other sizes can be customized. | |

| Sizes | Minimum.10*10mm |

| 2500*3600 | |

| Edges | Clear cut edges,Simple grinding edges, polished edges, customized edges |

| Application | Longer using-time,mostly be used in luxury areas, hotels,and bathrooms. |

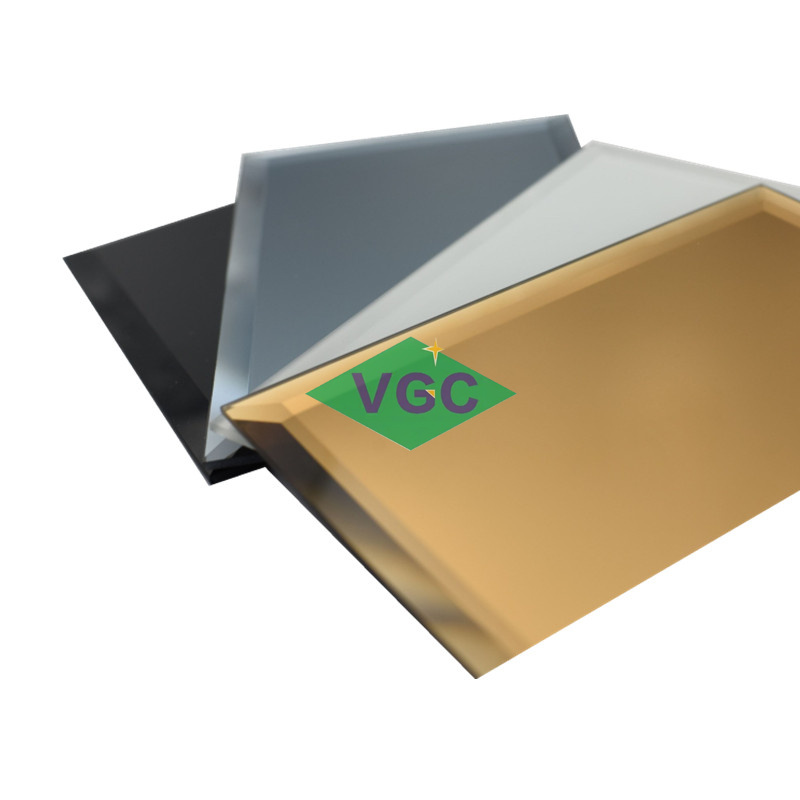

Large Size Silver mirror glass vs. aluminum mirror

Manufacturing Process:

Silver mirrors are made by coating a sheet of glass with a reflective layer of metallic silver. The process usually involves applying a layer of silver nitrate solution to the glass surface and then reducing it with a reducing agent to form a layer of metallic silver. The silver layer is then covered with a protective layer of paint or lacquer to prevent oxidation and scratching.

Aluminum mirrors, on the other hand, are made by depositing a layer of aluminum onto a sheet of glass or plastic. This is done using a process called vacuum deposition, in which the aluminum is evaporated in a vacuum chamber and allowed to condense onto the surface of the glass or plastic. The thickness of the aluminum layer can be controlled to achieve the desired level of reflectivity.

Reflectivity:

Silver mirrors are generally more reflective than aluminum mirrors. This is because silver is a better reflector of light than aluminum. Silver mirrors can reflect up to 95% of the light that hits them, while aluminum mirrors usually reflect around 85% of the light.

Durability:

Silver mirrors are more durable than aluminum mirrors. The silver coating on a silver mirror is thicker than the aluminum coating on an aluminum mirror, which makes it more resistant to scratching and corrosion. However, silver mirrors are more sensitive to moisture and may tarnish over time if not properly protected.

Aluminum mirrors are less durable than silver mirrors because the aluminum coating is thinner and more susceptible to scratching and corrosion. However, aluminum mirrors are more resistant to moisture and do not tarnish like silver mirrors.

Cost:

Silver mirrors are generally more expensive than aluminum mirrors due to the cost of silver and the more complex manufacturing process involved. Aluminum mirrors are less expensive to produce because aluminum is more abundant and the vacuum deposition process is simpler.

Overall, the choice between a silver mirror and an aluminum mirror depends on the intended use and the required level of reflectivity and durability. Silver mirrors are best suited for applications where maximum reflectivity and durability are required, such as in scientific instruments and high-end optics. Aluminum mirrors are often used in consumer applications such as mirrors for cars or home decor, where cost is a consideration and maximum reflectivity is not essential.

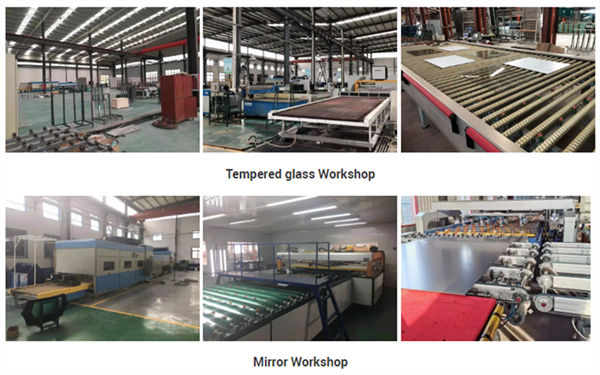

VIRTUE GLASS has always put product quality in the first place as product quality is the life of an enterprise. We try to implement the sense of quality to the heart of every employee,into the production of each link and details, strive for excellence. We take customer’s satisfaction as the main criterion for the assessment of all the production activities, customer demand is always our pursuit.

Buy Tinted Glass Mirror from China