What is Laminated Tempered Glass ?

Laminated Tempered Glass is a type of safety glass that is processed by heating it to a high temperature and then rapidly cooling it, which creates a surface compression that makes it stronger and more resistant to impact than regular glass. Laminated Tempered Glass is commonly used in applications where safety is a concern, such as in car windows, shower doors, and smartphone screens. If tempered glass does break, it will shatter into small, rounded pieces instead of sharp, jagged shards, reducing the risk of injury.

The process of Laminated Tempered Glass involves heating it to a temperature of around 620 to 680 degrees Celsius (1150 to 1260 degrees Fahrenheit) and then rapidly cooling it with jets of air. This process creates a surface compression in the glass that makes it up to five times stronger than regular glass of the same thickness.

The surface compression on the Laminated Tempered Glass makes it more resistant to bending, impact, and thermal stresses. This is why tempered glass is commonly used in applications where safety is a concern, such as in car windows, shower doors, patio doors, skylights, and architectural glass features.

In addition to its strength and safety features, Laminated Tempered Glass has other benefits. For example, it is heat-resistant, which makes it ideal for use in oven doors and fireplace screens. It is also more scratch-resistant than regular glass, which makes it a popular choice for phone screens and other electronic devices.

If Laminated Tempered Glass does break, it shatters into small, rounded pieces instead of sharp, jagged shards. These small pieces are less likely to cause injury, as they are less likely to puncture skin or cause deep cuts.

Overall, the Laminated Tempered Glass is a strong, durable, and safe material that is widely used in a variety of applications.

Laminated-Tempered-Glass

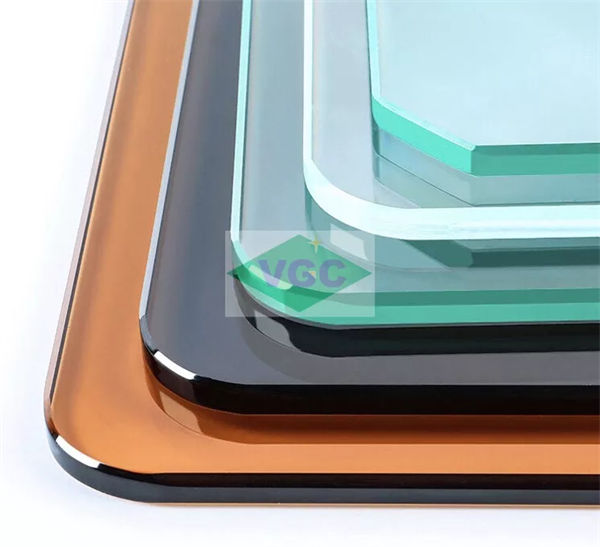

polished-edge-tempered-glass-768×768

Custom Safety Glass Toughened Glass

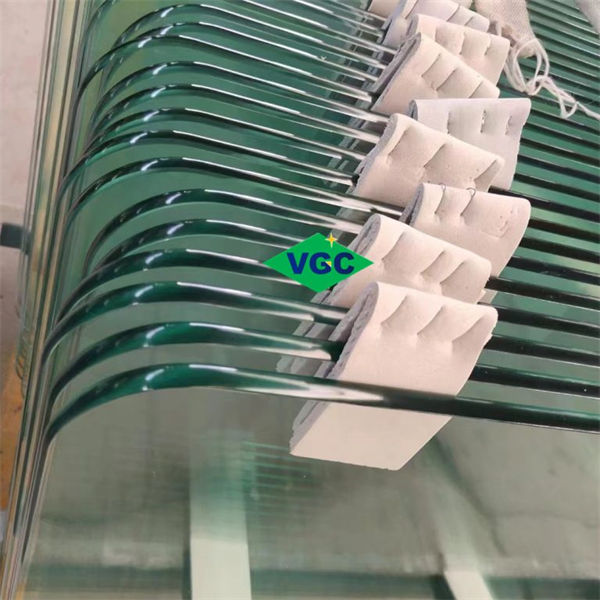

Curved-Tempered-Glass (1)

VGC Curved Tempered Glass Virtue Glass

Glass-Table-Top

Tinted Toughened Tempered Glass

Specification Of Safety Laminated Tempered Glass

| Product | Laminated Tempered Glass |

| Shapes | Rectangle,Square, Round, Fan shaped,triangle and other customized |

| Thickness | 1mm 2mm 3mm 4mm 5mm 6mm 8mm 10mm 12mm (1/8″, 5/32″, 3/16″, 1/4″, 3/8″, 1/2″, 3/4″) |

| Sizes | Customized |

| Edges | Bevel edges, Flat Polished Edges, Round Pencil Polished Edges, Seamed Edges etc. |

| Corners | Small Round Polished corners, Big Radius corners,Eased Corners,Clip and Polished Corners etc. |

Safety Laminated Glass VS. Laminated Tempered Glass

Sure, here’s some more information about the differences between tempered glass and laminated tempered glass:

- Strength: Laminated Tempered Glass is generally stronger than laminated glass of the same thickness, but laminated glass is better at resisting penetration.

- Breakage: When Laminated Tempered Glass breaks, it shatters into small, rounded pieces that are less likely to cause injury. When laminated glass breaks, it stays in place due to the inter-layer of plastic, which reduces the risk of injury from flying glass shards.

- Sound insulation: Laminated Tempered Glass provides better sound insulation than tempered glass, due to the interlayer of plastic which dampens sound waves.

- UV protection: Laminated-Tempered-Glass provides better protection against UV rays than tempered glass, due to the interlayer of plastic which filters out a significant amount of UV radiation.

- Applications: Laminated Tempered Glass is commonly used in situations where there is a high risk of impact, such as in car windows and shower doors. Laminated glass is commonly used in situations where security is a concern, such as in storefronts and bank teller windows.

- Cost: Laminated Tempered Glass is generally more expensive than tempered glass, due to the additional processing required to laminate the glass layers together.

In summary, Laminated Tempered Glass is stronger and better at resisting impact, while laminated glass provides better sound insulation, UV protection, and security. The choice between the two depends on the specific application and the level of safety and security required.

TEMPERED-VS-LAMINATED

TEMPERED VS LAMINATED GLASS

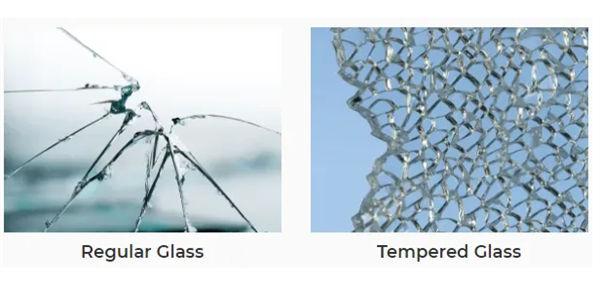

Laminated Tempered Glass VS Regular Clear Float Glass

Sure, here’s some additional information about the differences between safety tempered glass and clear float glass:

- Strength: Safety Toughened Tempered Glass is much stronger than clear float glass. It is up to five times stronger than regular glass of the same thickness, which makes it more resistant to impact and other types of stress. This is due to the tempering process, which creates a surface compression that makes the glass more durable.

- Safety features: Safety Toughened Tempered Glass is designed to break into small, rounded pieces when shattered, which reduces the risk of injury from flying glass shards. Clear float glass, on the other hand, can break into sharp, jagged shards that can cause serious injury.

- Applications: Safety Toughened Tempered Glass is commonly used in situations where safety is a concern, such as in car windows, shower doors, and architectural glass features. Clear float glass is commonly used in situations where clarity and transparency are important, such as in windows, mirrors, and tabletops.

- Thermal resistance: Safety tempered glass is more resistant to thermal stress than clear float glass. It can withstand sudden changes in temperature without breaking or cracking. This is due to the tempering process, which makes the glass more durable and able to withstand thermal shock.

- Manufacturing process: Safety Toughened Tempered Glass is made by heating regular glass to a high temperature and then rapidly cooling it. This creates a surface compression that makes the glass stronger and more durable. Clear float glass, on the other hand, is made by floating molten glass on a bed of molten metal to create a smooth, uniform surface.

- Cost: Safety tempered glass is generally more expensive than clear float glass, due to the additional processing required to make it. However, the added strength and safety features may make it worth the extra cost in certain applications.

In summary, safety Toughened Tempered Glass is a much stronger and safer option for applications where safety is a concern, while clear float glass is a more economical choice for applications where clarity and transparency are important but safety is not a major concern. The choice between the two depends on the specific application and the level of safety and durability required.

TEMPERED-GLASS-VS-REGULAR-GLASS

SAFETY TEMPERED VS REGULAR CLEAR GLASS

The Application of Laminated Tempered Glass

- Glass doors: Toughened Tempered Glass is commonly used in glass doors, such as patio doors and shower doors. It is strong and resistant to impact, which makes it safer than regular glass. If tempered glass does break, it breaks into small, rounded pieces that are less likely to cause injury.

- Windows: Toughened Tempered Glass is used in windows that are close to the ground or in high-traffic areas. It is also used in skylights and other types of windows that are more vulnerable to impact or breakage.

- Automobiles: Toughened Tempered Glass is used in the side and rear windows of cars and trucks. It is safer than regular glass because it shatters into small, rounded pieces when broken.

- Furniture: Toughened Tempered Glass is often used in furniture, such as glass tabletops and shelves. It is strong enough to support the weight of objects placed on it, and is resistant to scratches and other types of damage.

- Storefronts: Tempered glass is used in storefronts and display cases because it is strong and resistant to impact. It provides a high level of security and protection against break-ins and theft.

- Electronic devices: Toughened Tempered Glass is commonly used as a screen protector for smartphones and tablets. It provides a high degree of protection against scratches, cracks, and other types of damage.

In summary, Toughened Tempered Glass is a type of glass that is stronger and safer than regular glass. It is commonly used in applications where safety and durability are important considerations, such as in glass doors, windows, automobiles, furniture, storefronts, and electronic devices.

The Advantages of Laminated Tempered Glass

- Safety: Laminated Tempered Glass is designed to be safer than regular glass. It is strong and resistant to impact, and when it does break, it shatters into small, rounded pieces that are less likely to cause injury.

- Strength: Laminated Tempered Glass is stronger than regular glass because it undergoes a heat treatment process that makes it more resistant to breakage and damage.

- Durability: Laminated Tempered Glass is more durable than regular glass because it can withstand higher levels of stress and impact without breaking.

- Heat resistance: Toughened Tempered Glass is more heat-resistant than regular glass. It can withstand high temperatures without cracking or breaking, which makes it a good choice for use in applications where high temperatures are a concern.

- Versatility: Laminated Tempered Glass is a versatile material that can be used in a wide range of applications, from glass doors and windows to furniture and electronic devices.

- Transparency: Laminated Tempered Glass is transparent, which makes it an attractive choice for applications where clarity and visibility are important.

- Customization: Laminated Tempered Glass can be customized to meet specific design and functional requirements. It can be cut into different shapes and sizes, and can also be tinted or coated to enhance its properties.

Overall, the key words associated with tempered glass reflect its strength, durability, safety, versatility, and customized/

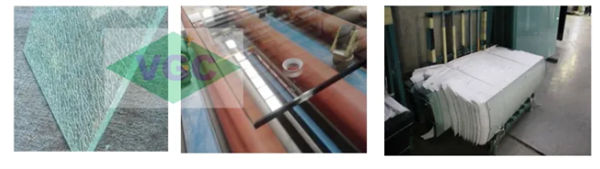

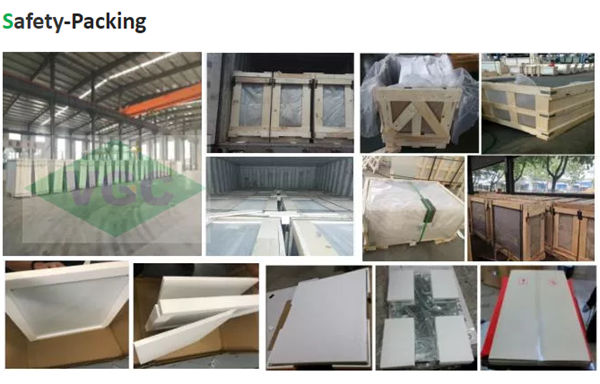

SAFETY-PACKING-OF-TEMPERED-GLASS

SAFETY PACKING OF TEMPERED GLASS

Why Choose Us?

-

Strict Quality&Detail control are the life of the company.

-

Provide overall solution.Establish real trust-worthy partnership.

-

Clients cooperated together, we can ensure no loss happened.

-

Factory competitive prices and best services.

-

Factory Monthly output can reach to 30000 sqm.

-

Established a strict quality management system.

-

Professional R&D Team, can customized for clients.

VIRTUE GLASS has always put product quality in the first place as product quality is the life of an enterprise. We try to implement the sense of quality to the heart of every employee,into the production of each link and details, strive for excellence. We take customer’s satisfaction as the main criterion for the assessment of all the production activities, customer demand is always our pursuit.

VIRTUE-GLASS-VGC-2

VIRTUE GLASS VGC

VIRTUE-GLASS-VGC-QUALITY