Find Modern Tempered Glass Door Panels from China Manufacturer | VGC Glass

VGC is Tempered Glass Door Panels Supplier/Safety Shower Doors Manufacturer. VGC Glass Door is made from clear tempered glass, frosted glass, Pattern tempered glass, and Ceramic Frit Glass etc. The tempered Glass Door Panels used as Patio Doors, Bathroom Doors, Garage Doors, Barn Doors etc.

Toughened Glass Door Panels customized sizes and processing, is the most popular safety door glass used that meet uniform building code standards.

Tempered Pattern Glass Moru 4mm-12mm

VGC Custom Tempered Pattern Glass Moru (4mm-12mm) – Low Iron, ...

Luxury Glass Wine Cabinet | Wine Display Showcase Manufacturer – VGC

At VIRTUE GLASS (VGC), we specialize in crafting premium luxury ...

Glass Curio Cabinet with Glass Door & Glass Shelf

Find Good Price Glass Display Showcase, Glass Curio Cabinet with ...

Good Price 8mm-12mm Transparent Glass Door Clear Tempered Glass Door

Good Price 8mm 10mm 12mm Transparent Glass Door Factory and ...

8mm Frameless Glass Shower Doors with Good Price

8mm Frameless Glass Shower Doors with Good Price from China ...

6mm 8mm 10mm Clear Tempered Glass For Door China Supplier

Find the Best Price 6mm 8mm 10mm Clear Tempered Glass ...

Frosted Glass Door

Manufacturer 6mm 8mm Acid Etched Frosted Glass Door ...

VGC Good Price 6mm/8mm/10mm Toughened Glass Shower Door China Manufacturer VGC

Manufacturer of 6mm 8mm 10mm 12mm Toughened Glass Shower ...

The processing steps for (tempered)Tempered glass door panels involve several stages to ensure the final product meets high-quality standards. Here’s a detailed breakdown of the steps you provided:

1. Sourcing High-Grade Clear Float Glass

- Quality Inspection:

- Ensure the glass is free from defects such as scratches, bubbles, or other imperfections.

- Verify that the glass meets industry standards for clarity and strength.

- Material Selection:

- Use high-grade clear float glass, which is known for its uniformity and flatness.

2. Automated Cutting to Customized Sizes

- Precision Cutting:

- Use automated cutting machines to ensure accurate dimensions as per customer specifications.

- Measurement Tolerances:

- Strictly adhere to glass processing standards and control measurement tolerances to avoid errors.

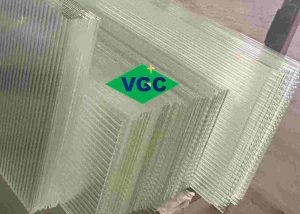

3. Edge Grinding and Polishing

- Edge Grinding:

- Grind the edges of the glass to the required finish (e.g., flat polished edges or simple grinding).

- Customization:

- Ensure the edges are processed according to the specific design or functional requirements of the door panel.

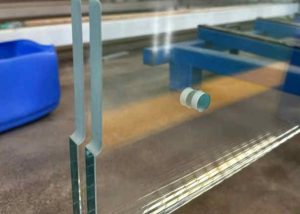

4. Drilling Holes or Cutting Notches

- Water-Jet Machines:

- Use water-jet cutting technology to drill holes or cut notches with precision.

- Quality Control:

- Ensure the holes and notches are accurately placed and meet the required specifications.

5. Cleaning and Drying

- Thorough Cleaning:

- Clean the glass to remove any dust, debris, or residue from the cutting and grinding processes.

- Drying:

- Ensure the glass is completely dry before packaging to prevent water spots or damage.

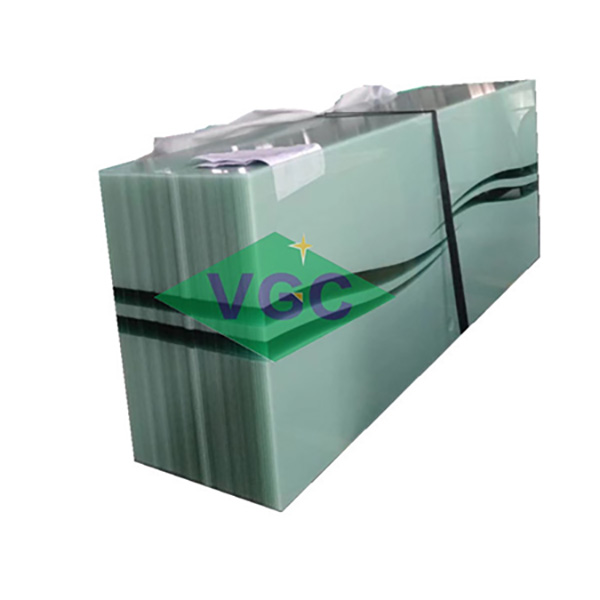

6. Packaging (Tempered Glass Door Panels)

- Protective Packaging:

- Pack the glass panels in standard plywood cases or cartons to prevent damage during transportation.

- Secure Handling:

- Ensure the packaging is sturdy and provides adequate protection against impacts or vibrations.

Additional Considerations:

- Tempering Process:

- After the above steps, the glass undergoes a tempering process (heating and rapid cooling) to increase its strength and safety.

- Final Inspection:

- Conduct a final quality check to ensure the tempered glass meets all safety and quality standards before dispatch.

By following these steps meticulously, you can produce high-quality toughened glass door panels that are durable, safe, and visually appealing.

What Glass can be used for Tempered Glass Door Panels?

SPECIFICATIONS OF VGC TEMPERED GLASS DOOR PANELS

| Product | Custom Tempered Glass Door panels |

| Types | Flat tempered glass door panels, curved tempered glass door panels,Fully tempered glass door,frosted glass Door, pattern tempered glass Door, Tinted Glass Door, LOW-E tempered glass door panels, insulated glass door. |

| Thickness | 6mm 8mm 10mm 12mm**** |

| Standard Sizes | 800*2000mm,900*2000MM,1000*2000MM,1200*2000MM,60*72inches,60*74.5inches,48*74.5inches etc. |

| Edges | Simple grinding edges, polished edges, customized edges |

| Application | Entrance doors, Patio Door, Bathroom Door, Garage Door, Barn Doors etc |

VGC Tempered Glass Door Panels Good Factory Cost

The price of VGC (Very Good Condition) Tempered Glass Door Panels can vary significantly depending on several factors, such as:

Key Factors Affecting Price:

- Glass Thickness:

- Common thicknesses range from 6mm to 12mm. Thicker glass is more expensive.

- Size and Dimensions:

- Larger or custom-sized panels will cost more.

- Edge Finishing:

- Polished edges, Simple grinding edges, or other custom finishes may increase the price.

- Holes and Notches:

- Additional cutting or drilling for handles, hinges, or other features can add to the cost.

- Tempering Process:

- The cost of the tempering process itself is a significant factor.

- Quantity:

- Bulk orders often come with discounts.

- Location and Shipping:

- Transportation costs and regional market rates can influence the final price.

Estimated Price Range:

| CUSTOM GLASS SHOWER DOORS | $45-$110/SET |

| CUSTOM TEMPERED GLASS DOOR PANELS | $5-$12/SQM |

| FROSTED GLASS DOORS | $10-$14/SQM |

| GLASS BARN DOORS | $30-100/SET |

CONTACT US FOR EXACT GOOD PRICES CUSTOM TEMPERED GLASS DOOR

Email: sales.virtueglass@aliyun.com

Mob: 86-15064221779

Wechat: xinyixiongdi2017

VGC Custom Tempered Glass Door FAQs

Why Choose Us?

RELATED TOPICS OF TEMPERED GLASS DOOR PANELS

- Glass entry doors

- Frameless glass doors

- Interior glass doors

- Exterior glass doors

- Commercial glass doors

- Frosted glass doors

- Sliding glass doors

- Safety glass doors

- Modern glass doors

- Glass patio doors

- Double glazed glass doors

- Tempered glass door panels

- Shower glass doors

- Etched glass doors

- Transparent glass doors